Product Center

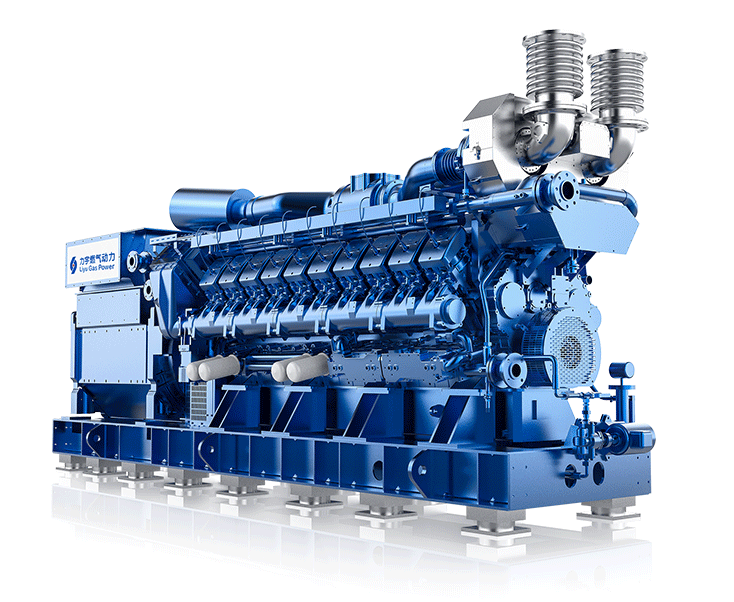

LY2000GH/L-Z

Digital system, intelligent operation

- Genset size(For the transportation size of genset, the components set separately must be considered separately)

Length(1) 7320mm

Width(1) 1700mm

Height(1) 2615mm

- Engine technical specifications

Cylinders 20

Bore / Stroke170mm/195mm

Displacement 88.5dm3

Displacement 1500rpm

Mean Piston Speed 9.75m/s

Ac Of Lube Oil0.2g/kW·h

- Genset technical parameters

Genset ModelLY2000GH/L-Z

Electrical Power(2)2000kW

Fuel Consumption 4890kW

Electrical Efficiency(3) 40.9%

Thermal Efficiency 44.6%

Nox(4) ≤500mg/Nm3

1.For the transportation size of genset, the components set separately must be considered separately

2.Refers to ISO3046/1, 50Hz Generator U=10kV,Cosphi=1.0, the minimum methane number of natural gas is MN70

3.Refers to ISO8525-1, 50Hz Generator U=10kV,Cosphi=1.0, the minimum methane number of natural gas is MN70

4.NOX emission: NOX≤0.5g NO2/Nm3(Content of dry exhaust gas in 5% O2)

For special gas and dual fuel gas applications, please consult our staff. The data herein are for reference only and not as binding value.

LY2000 unit features and advantages

-

Intelligent Operation

One-key start, automatic synchronization;

Automatic load distribution;

Emergency, failure shutdown protection;

Configure remote monitoring system.

-

Economical and Efficient

Efficiency reaches 41.6%;

Comprehensive utilization rate of energy reaches up to 87%;

Annual operational time reaches up to 8000 hours with a long period of overhaul maintenance;

Low consumption of lubricant with a lower cost of operation and maintenance;

Low emission with a dual guarantee for economical efficiency and environmental protection

-

High Applicability of Concentration Variation

Electric hybrid technology based on combustion regime;

Optimized air-fuel ratio algorithm;Dual-regulation of gas and air, applicable to concentration of a large fluctuation;

Rapid follow-up and response with a high reliability.

-

Adapt to Low Calorific Value Gases

Air inlet channel with a low flow resistance;

Adapt to methane concentration of 8% at minimum;

Industrial ECU with an Auto-Fit main control unit;

Output power and stability are invariable.

-

Design of High Reliability

Design featured by fire retardance, anti-explosion, knocking detection and control safety;

Advanced finite element analysis technology, ensuring a high-efficient operation under a variation of gas quality;

High-speed set with a stable operation and greatly improved reliability; Low-temperature emission reduces thermal load of piston, gas valve and booster;

Unique design in combustion chamber, effectively reducing cylinder and emission temperature; Separation design for strong and weak electricity avoids control intervention;

Multi-parameter cross-check technology enhances operational reliability of engine with an advanced technique, small volume and compact structure.

-

Apply Imported High-Quality Components

Further optimize gas control valve, realizing a more precise ignition time;

Advanced knocking control system can effectively detect knocking status;

Upgraded turbocharger can enhance operational capacity of generator set;

Generator set can precisely control air-fuel ratio upon a comprehensive upgrade of system.